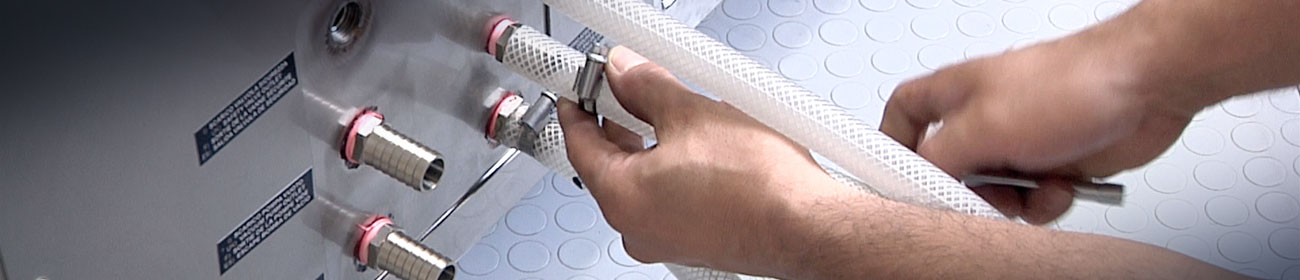

Easy to install

Energy saving

Easy to operate

Easy to clean

Short cooking cycle

Heating zones

Few manual operations

Indirect heating

Easy to load ingredients

Easy to download finished product

Excellent mixing

Recipes storage

Limited dimensions

Vacuum and positive pressure

Limited maintenance

Applications

Confectionery – Bakery – Chocolate shop – Gelateria

Industry – Farm

Jam and marmellate

Marzipan

Almond/pistachios/hazel nuts/pine nuts/walnuts paste

Pastry/chocolate/coffee cream

Gelato bases

Topping

Glossy icing

Caramel

Ganache

Praline

Fruit juice-fruit paste-fruit purea

Jelly fruit

Pasta choux

Gastronomy- Canteen – Catering – Ready meal

– Convenience food – Farm – Supermarket

Doughs

Sauces

Paste

Preserves

Mashed potato

Patè

Bechamel

Mayonnaise

Tuna sauce

Hummus and Tahina

Ketchup

Pesto

Meat sauce

Risotto

Baby food

Vegetable velvety

Vegetable soup

Laboratory – Diary industry – Farm

Process cheese

Spreadable cheese

Yoghurt

Mozzarella cheese dough

Tofu