Since I started working, I have dealt with technical assistance all over the world and I have learned that simplicity and easy of use of whichever machinery are the most important characteristics for clients as well as for engineers.

In one of these working experience (from 2002 to 2005) when I worked as a technician in a company operating in this field, that now are one of our competitors, I had the chance to realize what a client wants when purchase these machines.

During a second short experience in packaging field (2006), I had the chance to know the magnetic induction technology employed to a different use and being an electric technician, I have studied the potentiality as well as the different possibility of use, for more than a year.

In 2007 I realized the huge potentiality of this technology and I decided to put myself to test creating, in my cellar, a cooking/cutter device adapting the MAGNETIC INDUCTION TECHNOLOGY to heat products.

After the first two attempts (two prototypes were manufactured) I realized, I had in my hands the chance to offer to my potential clients a system able to work food products, performing an energy consumption much inferior than the classic steam technology, performed by my competitors, with an incredible ease of use.

Then I carried on with my projects finding technical solution in order to simplify the engineers work and relying on an excellent designer, we have drawn the first machine. Afterwards, thanks to good suppliers equipped with laser cutting, welding and milling, we have created all pieces that in 2008 let me assemble the first Rs-20 (still operating at our first client’s factory).

The first RS-20 has been tested by a lot of clients (chefs, cooks, pastry chefs) I received acclaims and compliments, but also comments which let me understood the weak points of my project in order to modify the machine to let it be more functional for the use required, I followed carefully clients requirements and I have planned and created different machines keeping the same philosophy.

Interested toward my machines as well as market request increased, therefore I realized I had to turn up my activity.

In 2013, together with an old friends, we started to think how to settle a company which put client as a partner promoting idea to examine and actualize, a company where creating solid, high tech and ease to use machines, a small and dynamic company based on concreteness and reliability, therefore on February 2014 RS Tecnology srl was born.

We moved in a small building, placed in Castello d’Argile where you can find offices, demo room as well as machine assembling.

during these last years we have planned our systems by means of software (“Autocad”, “Top”, Solid Edge”, Solid Works”, Autodesk Inventor”, etc.), thanks to these softwares we have created the Robot System machine range from 10 to 250 liters as well as the Steril System autoclave range from immersion 60 liters machine to rain system 130 liters.

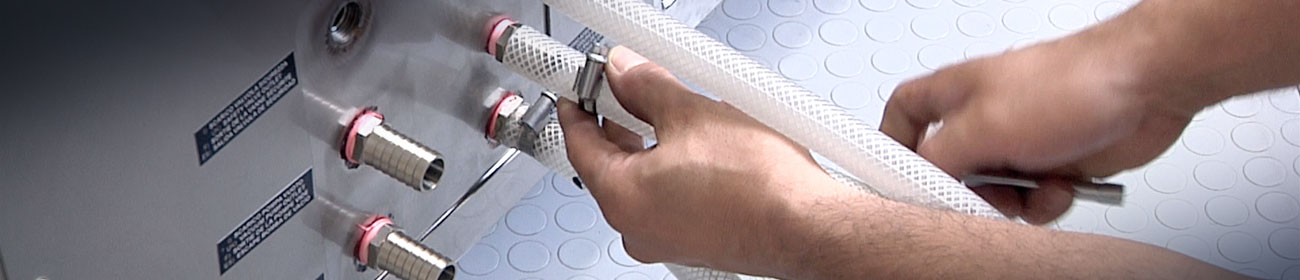

All our machines parts are drawn, then they are ordered and created by very reliable suppliers which take also care of machine mechanic assembling. In our factory we set up the main part (MAGNETIC INDUCTION), we carry out mechanic and electronic tests in order to deliver an efficient high quality product. Since we know very well what we create and deliver, we guarantee all parts we designed for 3 years.

Putting substance above appearance, we have developed a production system which let us produce up to 4 machines monthly, in a small factory that is also used for spare parts. This arrangement, far from being showy let us reduce our costs without increasing machine prices.

We do care about keeping a low profile, but we do offer substance and concreteness, despite of appearance, this is the main feature we identify our company with.